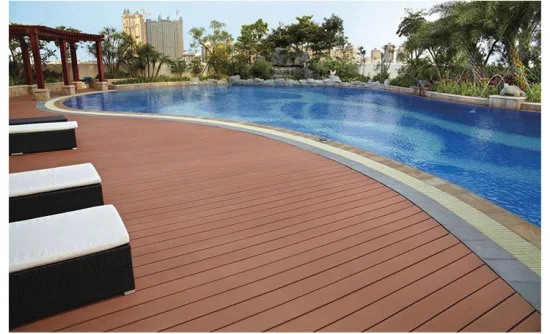

Swimming Pool Co-Extrusion Solid/Hollow Outdoor Floor Wood Plastic WPC Composite Deck

Package size per unit product 100.00cm * 20.00cm * 10.00cm Gross weight per unit product 5.000kg Advanges of Wood Plstic;

Basic Info

| Model NO. | wpc-deck |

| Environmental Standard | E1 |

| Function | Waterproof, Anti-Static, Thermal Insulation |

| Pattern | Wood Grain |

| Usage | Household, Outdoor |

| Customized | Customized |

| Material | Wood-Plastic Composite |

| Product Name | WPC Decking |

| Application | Outdoor |

| Surface Treatment | Sanding |

| Slip Resistance Dry | Pendulum Value≥36 |

| Slip Resistance Wet | Pendulum Value≥36 |

| Falling Mass Impact Resistance | None of The Speciments Shall a Failure with a Crac |

| Width | 140mm |

| Weight | 2470G/M |

| Density | 1350kg/M³ |

| Length | 2.7m 3.6m or Customized |

| Specification | 180*1220mm |

| Trademark | LT |

| Origin | Zhejiang, China |

| HS Code | 3925900000 |

| Production Capacity | 5000000 |

Packaging & Delivery

Package size per unit product 100.00cm * 20.00cm * 10.00cm Gross weight per unit product 5.000kgProduct Description

Advanges of Wood Plstic Composite

Natural Wood Texture,High Strength, Clean, Elegance Easy to Work,Eco-Friendly, Ideal deco material for outdoors Water-proof,Humidity-proof, Acid Base, Termite ProtectionHigh density,Resistant,No Rotting, Non-deformation Durable Temperaturebetween -40 to +60 Centi Degree No Painting,No Glue and LowMaintainence UV Protection,Stable ColorFully Environmental,Recyclable, Saving Forest Resource

Co-extrusion decking foor has solid, hollow 2 big kinds of product, apply to average household respectivelyand the business place oferowd dense.In each of the subtle grooves, all the polymer composite protective layer 360 - degree full - covering technology.Ayoid mildew, water cracking, discoloration, deformation and warping defects of traditional solid wood. preservative wood.common outdoor profile and other productsplastic wood co-extrusion products have solid wood color changes and texture, polymer protective layer 360-degreefull coverage technology.While comprehensively enhancing the product strength.we also ensure that the product can withstand the severe test of outdoor enyironment and avoid various defects of traditionasolid wood and anti-corrosion wood roducts.The rich color sclection of the wholc color system further strengthens itshigh-end status in the field of outdoor foor, so as to adapt to different cultural backgrounds worldwide.develop new products and meet different demands of customers.

| PRODUCT SPECIFICATION | ||||||||||||||||||

| Item | Standard | Requirements | Result | |||||||||||||||

| Slip Resistance Dry | EN 15534-1:2014 Section6.4.2 CEN/TS 15676:2007 | Pendulum value≥36 | Longtitudinal direction:Mean 72,Min 70 Horizontal direction:Mean 79,Min 78 | |||||||||||||||

| EN 15534-4:2014 Section 4.4 | ||||||||||||||||||

| Slip Resistance Wet | EN 15534-1:2014 Section6.4.2 CEN/TS 15676:2007 | Pendulum value≥36 | Longtitudinal direction:Mean 46,Min 44 Horizontal direction:Mean 55,Min 53 | |||||||||||||||

| EN 15534-4:2014 Section 4.4 | ||||||||||||||||||

| Falling mass impact resistance | EN 15534-1:2014 Section7.1.2.1 | None of the speciments shall a failure with a crack length≥10mm or a depth of residual indentation≥0.5mm | Max.Crack length(mm):No crack Max.Residual indenation(mm):0.31 | |||||||||||||||

| EN 15534-4:2014 Section 4.5.1 | ||||||||||||||||||

| Flexural properties | EN15534-1:2014 AnnexA | -F'max:Mean≥3300N,Min≥3000N-Deflection under a load of 500N Mean≤2.0mm,Max≤2.5mm | Bending Strength:27.4 MPa Modulus of elasiticity:3969 MPaMaximum load: Mean 3786N,Min 3540NDeflection at 500N: Mean:0.86mm,Max:0.99mm | |||||||||||||||

| EN 15534-4:2014 Section 4.5.2 | ||||||||||||||||||

| Creep behaviour | EN 15534-1:2014 Section7.4.1 | Known span in use: Mean S≤10mm,Max S≤13mm, Mean Sr≤5mm | Span: 330mm,Mean S 1.65mm,Max S 1.72mm,Mean Sr 1.27mm | |||||||||||||||

| EN 15534-4:2014 Section 4.5.3 | ||||||||||||||||||

| Swelling and water absorption | EN 15534-1:2014 Section8.3.1 | Mean Swelling:≤4% in thickness,≤0.8% in width,≤0.4% in lengthMax swelling:≤5% in thickness, ≤1.2% in width,≤0.6% in length Water absorption: Mean:≤7%,Max:≤9% | Mean Swelling:1.81% in thickness,0.22% in width,0.36% in length Max Swelling:2.36% in thickness,0.23% in width,0.44% in lengthWater absorption:Mean:4.32%,Max:5.06% | |||||||||||||||

| EN 15534-4:2014 Section 4.5.5 | ||||||||||||||||||

| Boiling Test | EN 15534-1:2014 Section8.3.3 | Water absorption in weight: Mean≤7%,Max≤9% | Water absorption:Mean:4.32%,Max:5.07% | |||||||||||||||

| EN 15534-4:2014 Section 4.5.5 | ||||||||||||||||||

| Linear thermal expansion coefficient | EN 15534-1:2014 Section9.2 | ≤50×10 K¹ | 34.2 x10 K¹ | |||||||||||||||

| EN 15534-4:2014 Section 4.5.6 ISO 11359-2:1999 | ||||||||||||||||||

| Resistance to indentation | EN 15534-1:2014 Section7.5 | Brinell hardness: 79 MPaRate of elastic recovery:65% | ||||||||||||||||

| EN 15534-4:2014 Section 4.5.7 | ||||||||||||||||||

| Heat reversion | EN 15534-1:2014 Section9.3 | Test Temperature:100ºCMean: 0.09% | ||||||||||||||||

| EN 15534-4:2014 Section 4.5.7 EN 479:2018 | ||||||||||||||||||

You may also like

Send inquiry

Send now